Stainless steel toilets are becoming increasingly popular due to their durability, stylish appearance, and resistance to corrosion. These toilets are commonly found in public restrooms, industrial facilities and high-traffic areas where sturdy construction is crucial. But have you ever wondered how these sturdy fixtures are made? Let’s take a fascinating journey into Kuge's factory and discover the intricate process of manufacturing stainless steel toilets.

The production of stainless steel toilets begins in professional factories equipped with advanced machinery and skilled workers. The process begins with the selection of high-quality stainless steel plates, which are critical to ensuring the durability and longevity of the finished product. The boards are carefully inspected for any defects before being sent for further processing.

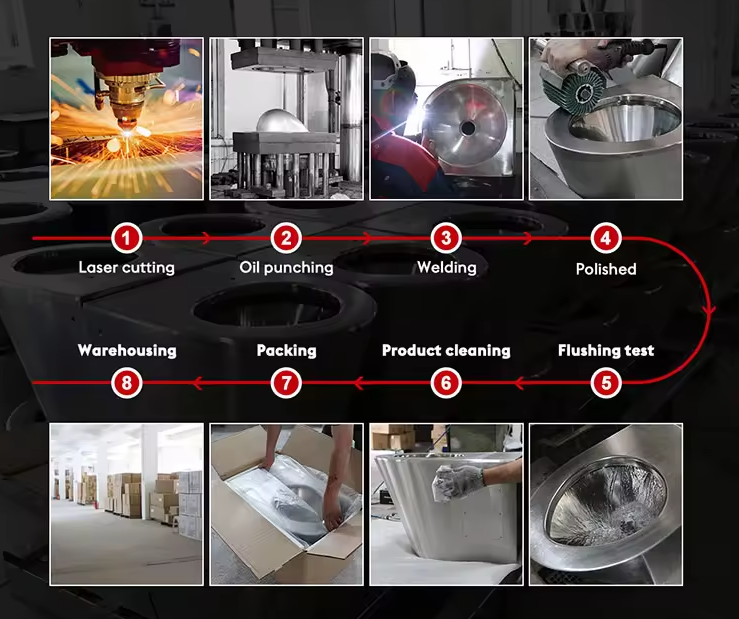

Once the stainless steel plates pass quality control inspections, they are cut into specific shapes and sizes using precision cutting machines. This step is crucial in creating the various components of the toilet, including the bowl, surrounding board, and other important parts. Precision cutting ensures each piece meets the exact specifications required for assembly.

After stainless steel parts are cut, they undergo a series of shaping and forming processes. Hydraulic presses and special molds are used to bend and form stainless steel plates into the desired shape. This step requires high precision to ensure the components fit together seamlessly during the assembly process.

Once the parts are formed, they are carefully welded together by skilled craftsmen. Welding is a critical step in the production of stainless steel toilets as it ensures the structural integrity and strength of the finished product. Welds are carefully inspected to ensure they meet the highest standards of quality and durability.

After the welding process is completed, the stainless steel components undergo a thorough cleaning and polishing process. This step is critical to achieving the signature luster and smooth surface that stainless steel is known for. The pieces are carefully polished to remove any imperfections and achieve a flawless brush finish.

After the components are polished, they will be assembled into the final product - a stainless steel toilet. Skilled workers carefully assemble the components together, ensuring each part is securely connected and aligned to create a functional and beautiful toilet. The assembly process requires precision and attention to detail to ensure the finished product meets the highest quality standards.

Once assembled, stainless steel toilets undergo rigorous testing to ensure performance and durability meet industry standards. Water pressure tests, leak checks, and functional assessments are performed to verify that the toilet can be used in a variety of environments. Only after passing these tests can the stainless steel toilet be delivered to the customer.

In short, the production of stainless steel toilets is a complex and meticulous process that requires advanced technology, skilled craftsmanship and a commitment to quality. From the selection of high-quality stainless steel plates to the precision cutting, forming, welding and assembly processes, every step is critical to creating durable and reliable fixtures. The next time you encounter a stainless steel toilet, you’ll appreciate the intricate process that goes into creating these strong and durable fixtures.