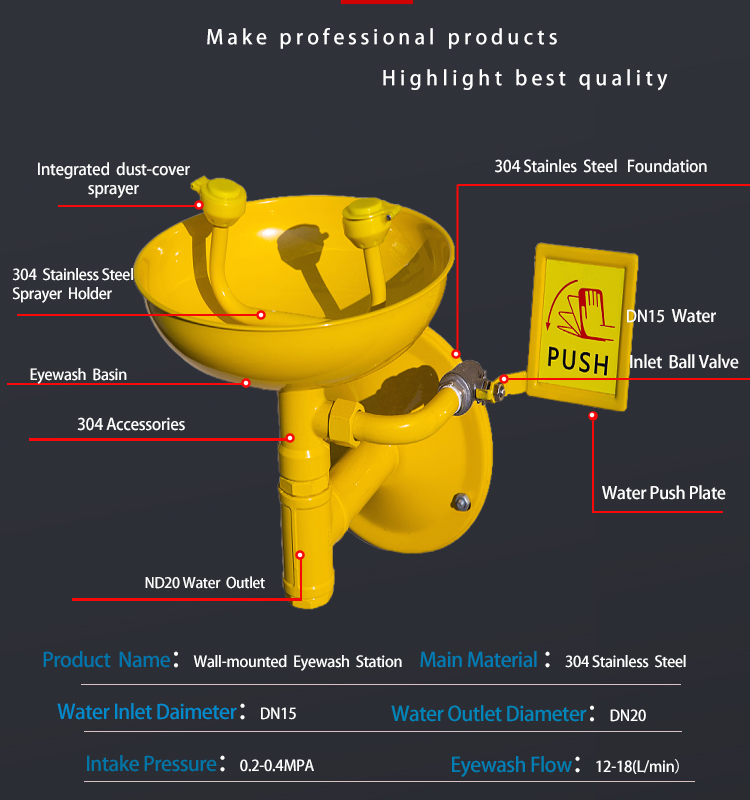

Material

| 304 Stainless steel |

| Model No. | KG-YX-BG-A(ABS) |

| Water inlet diameter | DN15 |

| Water outlet diameter | DN20 |

| Intake pressure | 0.2-0.4MPA |

Flow rate

| 12-18(L/min)

|

| Installation | Wall mounted |

The stainless steel emergency eye wash station is a robust and durable safety solution crafted to

meet the rigorous demands of industrial settings. Constructed from high-quality 304 stainless steel,

this eye wash station is designed to withstand harsh environments, resist corrosion, and provide

long-lasting performance. Emergency eye wash primary function is to deliver a gentle yet effective

stream of water to rinse contaminants from the eyes and face, minimizing the risk of further injury

and facilitating prompt medical attention when needed.

Features and Benefits

Durable Stainless Steel Construction

The eye wash station is manufactured using premium-grade 304 stainless steel, ensuring its ability

to endure exposure to chemicals, moisture, and other harsh elements commonly found in industrial

settings. This corrosion-resistant material not only prolongs the lifespan of the unit but also

maintains its structural integrity over time, providing reliable performance even in the most

demanding conditions.

Easy Activation Mechanism

Designed for quick and effortless operation, the eye wash station features a user-friendly activation

mechanism. Typically, this involves a push handle or pull rod that can be easily accessed and

activated even in emergency situations where panic or injury may impede fine motor skills. The

activation process is designed to be intuitive, allowing users to commence the flushing process

without delay, which is crucial in minimizing the severity of eye injuries.

Controlled Water Flow

The emergency eye wash is equipped with advanced flow control technology to ensure a

consistent and gentle water flow. This controlled flow is essential for effectively rinsing

contaminants from the eyes without causing additional harm or discomfort. The water streams are

engineered to provide comprehensive coverage of the eye area, ensuring that all parts of the eyes

and surrounding facial regions are adequately flushed. Some models feature adjustable flow

controls, allowing users to customize the water pressure and volume based on specific needs

and preferences.

Dust and Debris Protection

To maintain the hygiene and functionality of the spray heads, the eye wash station incorporates

protective dust covers. These covers prevent the accumulation of dust, dirt, and other particulates

on the spray nozzles, ensuring that the water streams remain clean and uncontaminated during

use. The dust covers are typically designed with a flip-top mechanism that is activated

simultaneously with the water flow, providing immediate access to the spray heads when needed.

Hands-Free Operation

For added convenience and efficiency, many stainless steel emergency eye wash station offers

hands-free operation. This feature allows users to keep their hands free to stabilize themselves

or tend to other injuries while the flushing process is underway. Hands-free activation can be

achieved through foot pedals, knee-operated levers, or other innovative mechanisms, ensuring

that the user can focus on the flushing process without the need to manually hold the activation

handle.

Versatile Mounting Options

The emergency eye wash station is designed to accommodate various mounting configurations to suit

different workplace layouts and requirements. It can be wall-mounted, floor-mounted, or installed on a

pedestal, providing flexibility in placement based on the specific needs of the facility. This versatility

ensures that the unit can be positioned strategically in areas where it is most accessible in case of

emergencies, such as near chemical storage areas, laboratory workstations, or industrial processing zones.

Materials and Components

The construction materials of the emergency eye wash station are selected for their durability,

corrosion resistance, and compatibility with emergency use. The primary body of the emergency eye

wash is crafted from stainless steel, offering superior resistance to rust and chemical degradation.

Applications

The stainless steel emergency eye wash station is a versatile safety solution applicable across various

industries where eye hazards are a concern. Its robust construction and reliable performance make

it suitable for use in environments such as:Industrial Manufacturing,Laboratories,Chemical Plants,

Construction Sites,Healthcare Facilities.